What Aviation Cleaning Crews Actually Do — And Why These Jobs Are Growing

Introduction and Outline

Airplane cabins need fast, detailed cleaning between flights. That single sentence sums up why ground cleaning teams sit at the heart of modern air travel: they operate on razor-thin schedules, follow strict safety and sanitation procedures, and still have to present a cabin that feels welcoming. The work touches reliability, safety, and the passenger experience—all at once. In most hubs, single-aisle jets may turn in 25–40 minutes, while widebody aircraft can run 60–90 minutes depending on catering, crew changes, and security checks. When the clock is tight, cleaning leaders think like air traffic controllers, sequencing tasks so nothing critical falls through.

Here is the roadmap for this article so you can skim or read deeply based on your goals:

– Turnaround time pressure and cleaning priorities: how teams triage tasks when minutes matter, with real-world time budgets and examples.

– Types of roles: cabin prep, disinfection specialists, and exterior cleaning crews; tools, training, and cross-checks that keep work safe and consistent.

– Airport vs. airline contractor work: hiring pipelines, scheduling realities, pay structures, and performance metrics.

– Quality assurance and career outlook: what hiring managers measure, how workers progress, and why demand remains resilient.

Why this matters: On-time departures depend on fast, accurate cabin resets; bacterial and viral contamination risk is mitigated by methodical disinfection; and customer perception can swing on small details like spotless tray tables or fresh-looking lavatories. Cleaning teams often arrive the moment deplaning starts, coordinating with gate agents, caterers, and maintenance technicians. A typical sequence might be: trash sweep and seat checks, high-touch surface disinfection, lavatory refresh, galley wipe-downs, aisle vacuuming, and final presentation checks. Each step is designed to be both efficient and auditable—supervisors often spot-inspect aisles or use checklists that align with airline and airport requirements. Whether you’re exploring a frontline role or managing a station, understanding this choreography will help you prioritize, communicate, and improve results under pressure.

Turnaround Time Pressure and Cleaning Priorities

Turn time is the period from when an aircraft parks to when it pushes back again, and it drives everything from gate utilization to crew costs. Cleaning leaders treat that window as a critical path: the sooner high-priority items are completed, the more buffer remains for presentation touches. For a 30-minute narrow-body turn, a realistic breakdown might be: 3–5 minutes for deplaning to clear the first half of the cabin; 15–18 minutes of parallel cleaning tasks; 4–6 minutes for final checks and security sweeps; and a 1–3 minute cushion to resolve last-minute issues. Widebody timelines stretch longer, but the logic stays the same—triage what matters most.

Common priority layers look like this:

– Safety-critical: clear aisles, unobstructed exits, working seatbelts, no foreign objects near seat tracks or door seals, clean and dry floors to prevent slips.

– Hygiene-critical: lavatory sanitation and restock, disinfection of high-touch points (armrests, tray tables, seatbelt buckles, overhead bin latches), quick response to spills and biohazards using approved procedures and PPE.

– Presentation-critical: visible crumbs and litter removal, spot-cleaning windows and tray tables, straightening safety cards, fluffing pillows or headrest covers where used.

– Time-permitting extras: deeper seat pocket sorting, thorough galley polishing, detailed carpet treatment in high-traffic zones.

Trade-offs are inevitable. If a flight arrives late with only 22 minutes to turn, the supervisor may reassign two team members to focus solely on lavatories and the forward cabin, where boarding begins. A coffee spill on the aisle takes precedence over carpet grooming because sticky floors threaten both safety and perception. In winter, deicing fluid tracked into the entry may demand repeated passes to eliminate residue. Reliable teams build in micro-buffers: they stage trash liners, load sanitizer bottles at the jet bridge, and pre-plan who mirrors whom in the opposite aisle to avoid congestion. Data-driven stations analyze logs to find slow points—perhaps lavatory restock is slipping because supplies sit too far from the gate, or vacuum cords cross aisles and slow traffic. Small adjustments, like zone-based caddies or cordless tools where approved, shave minutes without sacrificing standards. Over time, these micro-optimizations compound into higher on-time performance and fewer last-second scrambles.

Roles Explained: Cabin Prep, Disinfection, and Exterior Cleaning

Cleaning work divides into distinct roles so crews can move quickly without tripping over each other. This article breaks down what crews do and why the job’s in demand. In the cabin, “prep” is the reset: remove trash, realign seat belts, check seat pockets, and stage amenities. Disinfection targets high-touch surfaces and spill-prone zones with products that require specific dwell times to be effective. Exterior cleaning, a separate discipline, tackles the aircraft’s skin and sensitive surfaces under strict safety rules.

Cabin prep teams typically handle:

– Rapid trash sweeps and waste segregation in line with airport rules.

– Seat area resets: belts crossed and visible, life vests undisturbed, safety cards tidy, windows spot-cleaned if visibly soiled.

– Aisle and galley organization: carts parked, latches secure, surfaces wiped of crumbs or grease where time allows.

– Vacuuming patterns that favor center aisles first, then zones, to avoid blocking boarding.

Disinfection specialists focus on efficacy and consistency. They apply approved disinfectants to armrests, tray tables, buckles, headrests, overhead bin latches, lavatory door handles, faucets, and flush buttons. Dwell time matters—many products require a minute or more before wiping. Some teams use electrostatic sprayers during overnight or extended ground time because coverage is thorough and repeatable; on short turns, targeted wipes dominate to avoid moisture buildup. Biohazard response follows a clear flow: isolate the area, don PPE, apply absorbent agents, sanitize, bag waste according to protocol, and document the event.

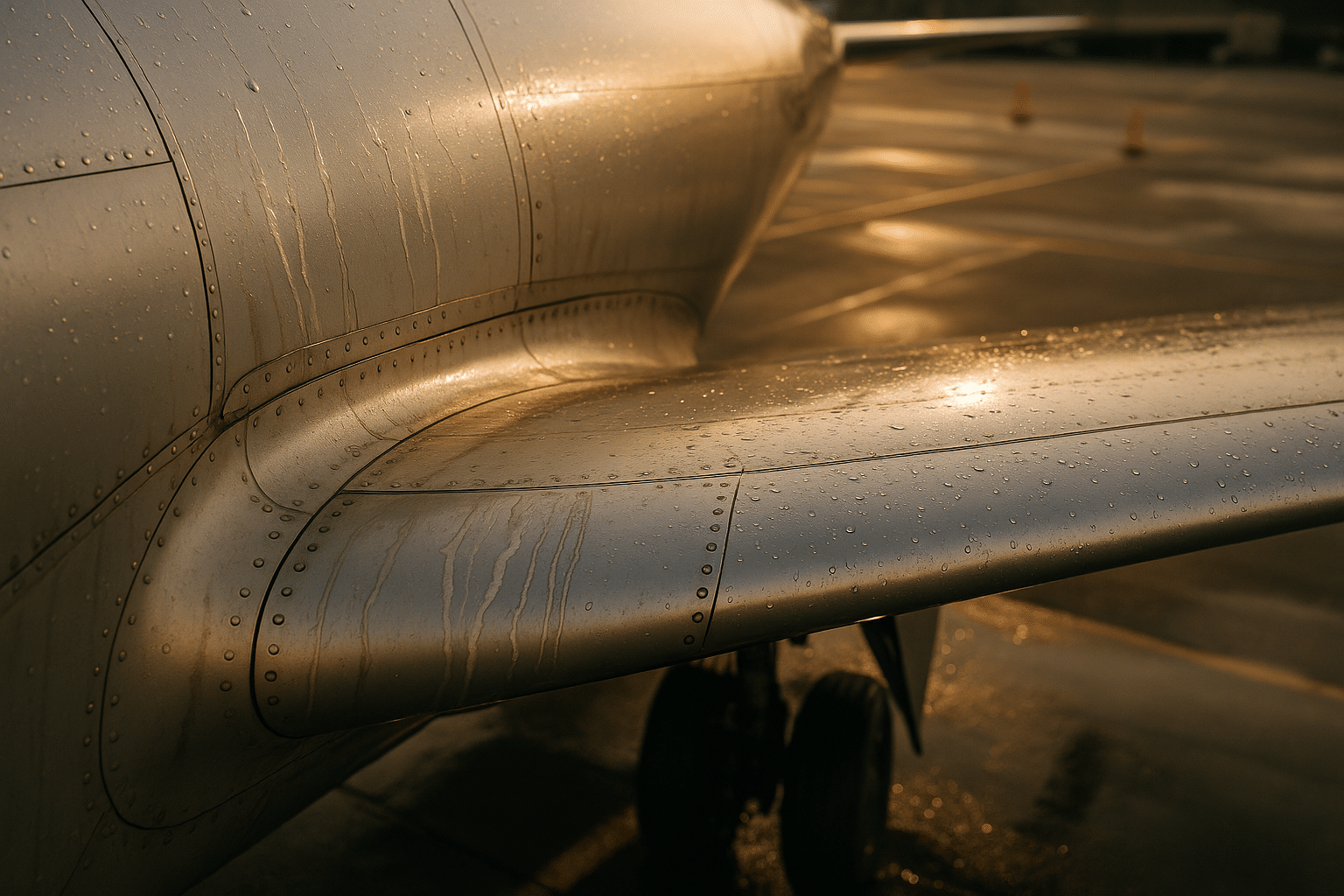

Exterior cleaning crews work when aircraft remain on the ground longer or during scheduled maintenance windows. Tasks include belly washes to remove oil and residue, leading edge wipe-downs to clear bugs and grime, window polishing to reduce streaks and glare, and spot-cleaning engine inlets and landing gear doors (avoiding sensors and static ports). Safety is non-negotiable: cones mark work zones, ground points mitigate static, and teams coordinate with ramp control to keep clear of fueling and tug operations. Environmental compliance is also central; runoff must be captured or directed to approved drains, and detergents are selected with local regulations in mind. Because exteriors present large, curved surfaces, crews adopt methodical passes to prevent missed bands or visible swirl patterns. Done well, exterior cleaning improves inspection visibility for maintenance and reduces drag from residue build-up, supporting both appearance and performance.

Airport vs. Airline Contractor Work: What Changes and What Stays the Same

Two employment paths dominate aviation cleaning: working directly for an airline or joining a contractor that serves multiple carriers. On paper, the job looks similar—cleaning cabins, sanitizing touchpoints, and meeting a schedule. In practice, the day-to-day can feel different because training, equipment, performance metrics, and career ladders vary by employer.

Direct airline roles commonly feature:

– Standardized training academies aligned with company procedures and aircraft types in the fleet.

– Closer integration with flight and gate operations, which can streamline communication and resequencing when delays hit.

– Paths to cross-train into ramp, catering liaison, or cabin maintenance support roles, depending on station size and policies.

– Performance reviews tied to internal metrics like cabin audit scores, on-time departure contributions, and customer feedback trends.

Contractor roles often provide:

– Exposure to multiple carriers, meaning procedures change by assignment; this builds adaptability and broader equipment familiarity.

– Variable schedules that flex with airport peaks and seasonal demand, producing more overtime opportunities in busy periods.

– Advancement routes into shift lead, trainer, and station supervisor positions across accounts and airports.

– Service-level agreements (SLAs) that define turnaround windows, audit criteria, and penalties or bonuses for performance.

Pay and benefits differ by market, employer, and experience. Some stations pay shift differentials for overnight work; others emphasize attendance bonuses tied to perfect on-time streaks. In high-cost cities, hourly rates trend higher, while smaller stations may trade pay for faster promotion windows. Union representation varies and can influence scheduling practices, grievance procedures, and wage progression. Regardless of employer, skills that consistently matter include: time management, communication with gate and cabin crews, safe chemical handling, and an eye for the “first impression” details customers notice. Teams that master those fundamentals post stronger audit results and spend less time on rework. If you’re deciding between paths, consider your learning style and goals: an airline can offer depth within one system, while a contractor can offer breadth across many systems—both are valid ways to grow.

Quality Assurance, Career Paths, and What’s Next (Conclusion)

Quality in aviation cleaning is measured, not guessed. Supervisors use checklists, random audits by zone, and sometimes rapid tests that detect residual organic matter to validate sanitation steps. Spot-inspections target frequent-fail items: sticky tray tables, missed seat belts at window seats, mirror streaks in lavatories, and crumbs along seat tracks that vacuums can skip on quick passes. Simple process controls reduce misses—pairing teammates to mirror aisles, staging caddies for each third of the cabin, and enforcing a “touch it once” rule for trash and amenities. Documentation closes the loop: biohazard events, delays linked to cleaning, and component issues (like a broken latch discovered during a wipe) are logged, creating a feedback trail for maintenance and operations.

Career development is concrete and attainable. Entry-level agents can advance to zone lead in months by demonstrating speed and accuracy; from there to trainer, quality auditor, or shift supervisor. With cross-training, some move into ramp operations, catering coordination, or cabin maintenance support. Certifications in chemical safety, lift and ladder use, and airside driving expand eligibility for specialized tasks like exterior washes or night-shift deep turns. Soft skills matter: clear radio etiquette, calm triage under pressure, and constructive handoffs to boarding agents signal readiness for leadership. Demand is resilient because aircraft utilization remains central to airline economics, and travelers expect visible cleanliness. Airlines rely on this role more than you’d think.

Looking ahead, several trends are shaping the field:

– Smarter tools: electrostatic application for deep turns, color-coded cloth systems to prevent cross-contamination, and lightweight vacuums that reduce strain.

– Process analytics: stations track average minutes per zone, re-clean rates after audits, and delay causes to target bottlenecks.

– Sustainability: airports are encouraging detergents and methods that reduce runoff and waste without sacrificing efficacy.

– Human factors: ergonomic training and rotation schedules cut fatigue, boosting both quality and safety.

Summary for job seekers and supervisors: if you’re considering this line of work, expect a fast pace, clear standards, and a team culture where each person’s minutes matter. Build a habit of prioritization and communication, and you’ll stand out quickly. For managers, invest in staging, simple checklists, and realistic staffing for peak banks; these levers pay off in audit scores and on-time performance. The role is hands-on, measurable, and increasingly skilled—an essential layer in the complex dance that gets an aircraft turned, boarded, and back into the sky on time.