Learn More About Contact Lenses

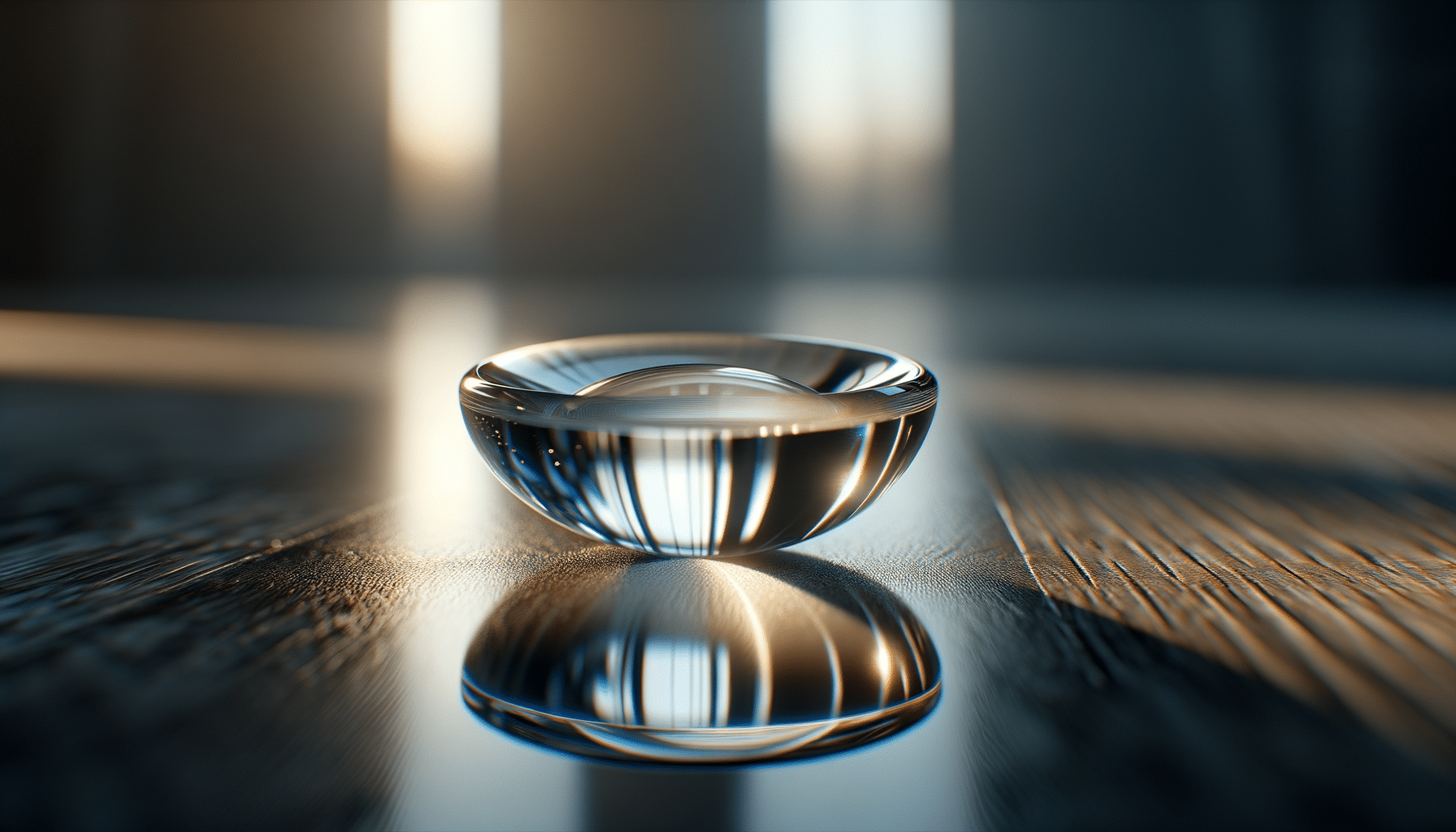

Introduction to Contact Lenses

Contact lenses are more than just a convenient alternative to traditional glasses; they offer a unique approach to vision correction that has advanced significantly over the years. As optical devices, they rest directly on the cornea of the eye, providing a natural field of view and eliminating the peripheral distortions that can occur with glasses. This article delves into the world of contact lenses, exploring their types, manufacturing processes, fitting procedures, and maintenance. By understanding these aspects, individuals can make informed decisions about their vision care options.

Types of Contact Lenses

The diversity in contact lens types caters to a wide array of vision correction needs and lifestyle preferences. Here’s a closer look at the different varieties available:

- Soft Contact Lenses: Made from gel-like, water-containing plastics, these lenses are known for their comfort and flexibility. They are particularly popular among users who seek ease of use and quick adaptability.

- Rigid Gas Permeable (RGP) Lenses: These lenses are durable and offer clear, crisp vision for most vision problems. Although they require a longer adjustment period, they are highly beneficial for correcting astigmatism.

- Hybrid Lenses: Combining the benefits of both soft and RGP lenses, hybrid lenses feature a rigid center with a soft outer ring, providing comfort alongside superior optical performance.

- Specialty Lenses: These include multifocal lenses for presbyopia, toric lenses for astigmatism, and scleral lenses for irregular corneas.

Each type of lens serves specific vision needs, and selecting the right one often involves considering factors like comfort, convenience, visual acuity, and eye health.

Manufacturing Processes of Contact Lenses

The journey of a contact lens from raw material to a vision-enhancing product involves intricate processes and precision engineering. Modern contact lenses are manufactured using advanced technologies to ensure high quality and safety standards. The primary materials used are hydrogel and silicone hydrogel for soft lenses, and durable polymers for RGP lenses.

The manufacturing process typically involves:

- Injection Molding: This is a common method for producing soft contact lenses, where liquid monomers are injected into molds and polymerized to form the lens shape.

- Lathe Cutting: RGP lenses are often crafted using this method, where a lathe machine cuts the lens from a solid lens blank, followed by polishing to achieve the desired optical properties.

- Spin Casting: Used for soft lenses, this process involves spinning a mold at high speeds to distribute the lens material evenly, creating a smooth, curved surface.

Each manufacturing technique is selected based on the type of lens and desired characteristics, ensuring that the lenses meet specific vision correction requirements and comfort levels.

Fitting and Prescribing Contact Lenses

Proper fitting and prescription of contact lenses are crucial for ensuring both comfort and optimal vision correction. The fitting process involves a detailed eye examination by an eye care professional, who will assess the curvature and diameter of the cornea, alongside other aspects like tear film quality.

During the fitting, the following steps are typically involved:

- Assessment of Vision Needs: The practitioner evaluates the patient’s vision correction requirements, considering factors such as nearsightedness, farsightedness, astigmatism, or presbyopia.

- Trial Lenses: Patients may be given trial lenses to wear for a short period to assess comfort and visual acuity.

- Final Prescription: Based on the trial results, a final prescription is provided, detailing the lens type, power, curvature, and other specifications.

The fitting process ensures that the lenses not only provide clear vision but also fit comfortably on the eye, reducing the risk of complications.

Care and Maintenance of Contact Lenses

Proper care and maintenance of contact lenses are essential to prevent infections and ensure long-term eye health. Here are some key practices to follow:

- Cleaning and Disinfecting: Use the recommended contact lens solution to clean and disinfect lenses daily. Avoid using water or saliva, as these can introduce bacteria.

- Storage: Store lenses in a clean, dry case and replace the case every few months to prevent contamination.

- Handling: Wash hands thoroughly before handling lenses, and always inspect lenses for any damage or debris before inserting them.

- Replacement Schedule: Adhere to the prescribed replacement schedule, whether it’s daily, bi-weekly, or monthly, to ensure optimal lens performance and eye health.

By following these care guidelines, contact lens wearers can enjoy clear vision while minimizing the risk of eye infections and other related issues.

Conclusion: Enhancing Vision with Contact Lenses

Contact lenses offer a versatile and effective means of vision correction, catering to diverse needs and preferences. Understanding the types of lenses, their manufacturing processes, fitting procedures, and maintenance requirements empowers users to make informed choices about their eye care. By prioritizing regular eye check-ups and adhering to prescribed care routines, individuals can enjoy the benefits of contact lenses while maintaining optimal eye health. Whether for daily use or special occasions, contact lenses continue to be a valuable tool in enhancing visual clarity and quality of life.